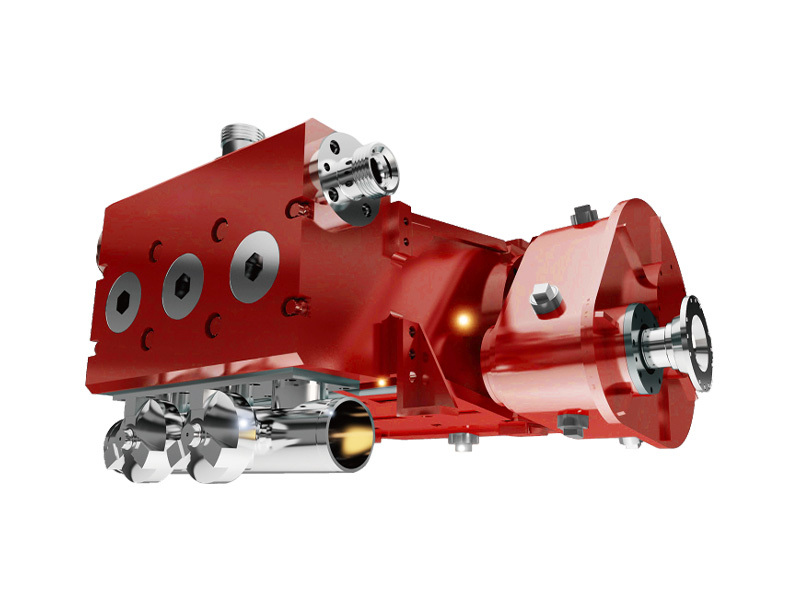

Application scope:

① Used for oil field fracturing trucks, for high-pressure liquid transportation,

② Mud pump, used for transporting mud or liquids containing suspended solids

③ Used for well repair and cementing equipment, for liquid transportation during drilling processes

④ Used specifically for large pumps in oil field fracturing trucks

⑤ Accept customized drawings

Product advantages:

① The crankshaft of the fracturing pump has high wear resistance and impact resistance, and can withstand working conditions of high pressure and high flow rate

② The crankshaft of the mud pump has high sealing and wear resistance characteristics to adapt to media containing abrasives such as sand particles

③ The crankshaft for well repair and cementing has high reliability and durability to adapt to long-term high-intensity operations

The Oil Pump Crankshaft is an extremely important component in the mechanical system, especially in the engine and other equipment.

1. Oil Pump Part

Functional Characteristics

The oil pump is responsible for transporting lubricating oil from the oil pan to various parts of the engine that need lubrication. It is like a precise "oil supply messenger" to ensure that the oil reaches various components, such as bearings, pistons, etc., at the right pressure. This is of vital importance for reducing friction, reducing wear and heat dissipation.

The design of the oil pump is efficient and adopts advanced pumping principles. It can stably provide sufficient oil under different working conditions of the engine. Whether it is the low flow demand when the engine is idle or the high flow demand at high speed, the oil pump can accurately respond.

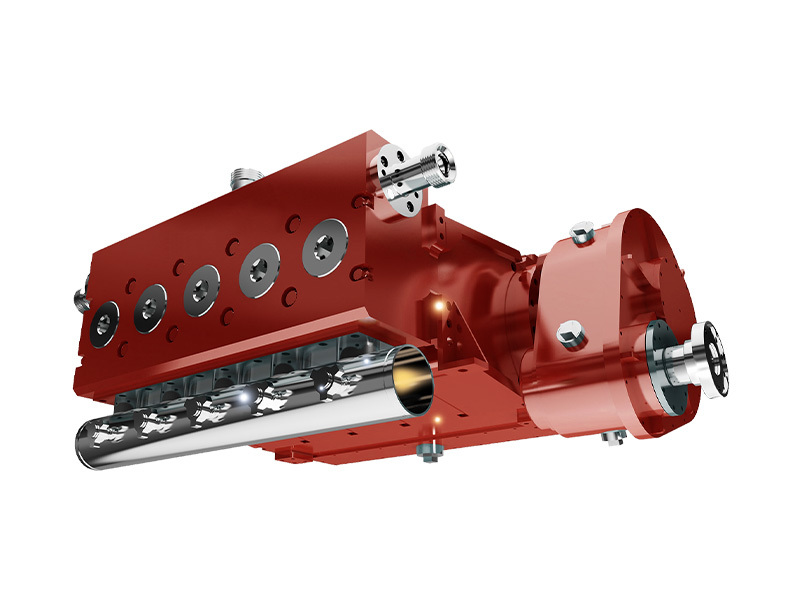

Structural Design

Its internal structure is compact and reasonable, and consists of key components such as pump body, gears or rotors. The pump body is usually cast with high-strength metal materials and has good sealing and pressure resistance. The machining accuracy of the gears or rotors is very high to ensure that the oil can be smoothly sucked in and pressed out.

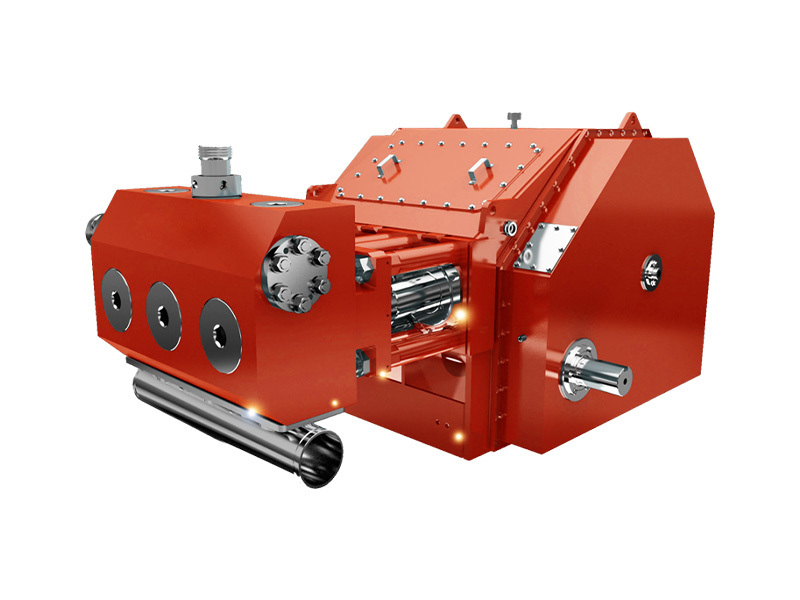

2. Crankshaft

Power transmission core

The Oil Pump Crankshaft is the power transmission hub of the engine. It converts the reciprocating motion of the piston into rotational motion, thereby driving other components such as flywheels and transmissions. The strength and toughness of the crankshaft are its key performance indicators because it has to withstand huge explosive force and torque.

During the working process, the rotation accuracy of the crankshaft directly affects the stability of the engine. To ensure this, the manufacturing process of the crankshaft is very strict, including precision forging or casting processes, as well as high-precision machining processes.

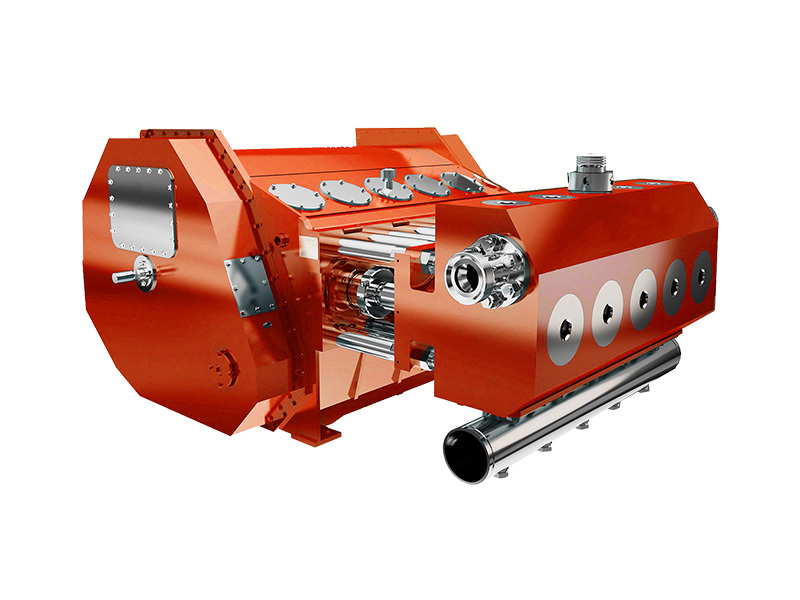

Material and durability

It is generally made of high-quality alloy steel materials, which have high strength, hardness and wear resistance after special heat treatment. The surface of the Oil Pump Crankshaft is also finely ground and polished to reduce friction and improve mechanical efficiency. At the same time, in order to prevent fatigue damage to the crankshaft during operation, its structural design also takes into account the uniformity of stress distribution to ensure reliable operation under long-term and high-intensity working conditions.

Keywords

Oil Pump Crankshaft

Contact Us

Classification